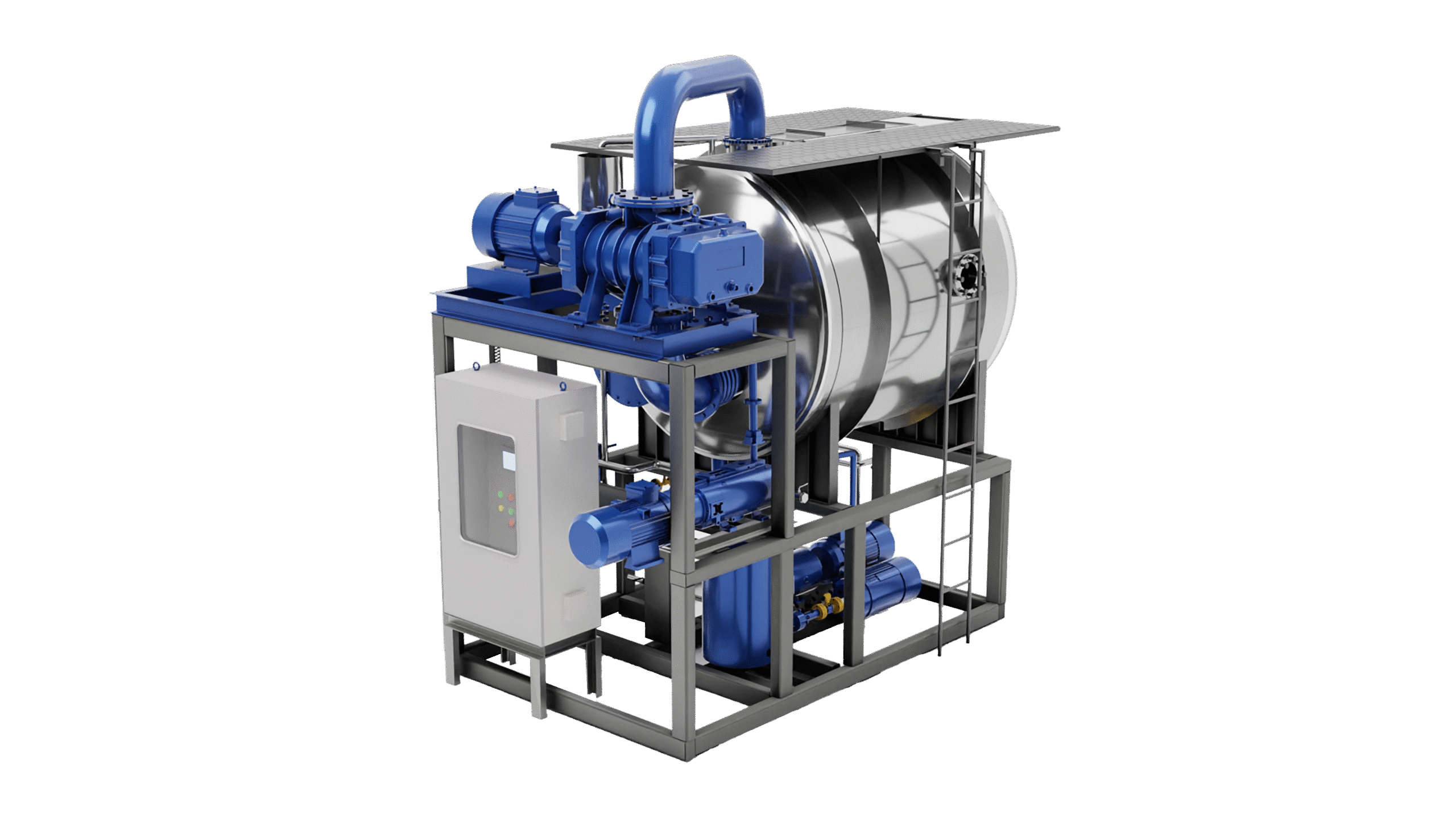

Mechanical Vapour Recompressors

ENHANCING ENERGY EFFICIENCY WITH KAY MECHANICAL VAPOUR RECOMPRESSORS

KAY Mechanical Vapour Recompressors (MVRs) are pivotal in modern industrial processes, particularly in applications requiring significant energy conservation and efficiency. By leveraging the principles of thermodynamics, KAY MVRs offer a sustainable solution for industries looking to reduce their energy consumption and operational costs.

Designed with cutting-edge technology, KAY MVRs sets a new standard for energy conservation and operational excellence across various industries.

UNDERSTANDING MECHANICAL VAPOUR RECOMPRESSION

Mechanical vapour recompression involves the capture and reuse of waste steam or vapour that is typically lost in various industrial processes. The core mechanism revolves around compressing low-pressure vapour to a higher pressure, which increases its temperature and enthalpy. This recompressed vapour can then be reused as a heat source within the same process, thereby minimizing the need for additional external energy input.

WHY CHOOSE KAY?

KAY International Pvt. Ltd. stands out as a leader in innovation, quality, and customer satisfaction. Here’s why you should choose KAY for your industrial needs

- Unmatched Quality and Reliability

At KAY, we are committed to providing products that are built to last. Our MVRs are engineered with precision using high-quality materials, ensuring durability and consistent performance even in the most demanding industrial environments.

- Innovative Technology

We pride ourselves on being at the forefront of technological advancements. Our team of experts continuously innovates to integrate the latest technologies into our MVRs, delivering superior efficiency, reduced energy consumption, and enhanced operational capabilities.

- Customized Engineered Solutions

Every industry has unique requirements, and we understand the importance of tailored solutions. KAY offers customized MVR designs to meet the specific needs of your applications, ensuring optimal performance and efficiency.

- Energy Efficiency

Our MVRs are designed with energy efficiency in mind

- Exceptional Customer Support

At KAY, customer satisfaction is our top priority. Our dedicated support team is available to assist you with selection, installation, and maintenance, ensuring that MVRs operate at peak efficiency. We provide comprehensive after-sales support and maintenance services to keep your operations running smoothly.

- Global Reach with Local Expertise

While we serve a global market, we understand the importance of local support. Our network of experts and partners ensures that you receive timely and effective service, no matter where your operations are located.

- Proven Track Record

With years of experience and a long list of satisfied clients, KAY has established a reputation for excellence. Our products are trusted by leading companies across various industries, a testament to our commitment to quality and reliability.

KEY BENEFITS OF KAY MVRs

Energy Savings: One of the most significant advantages of KAY MVRs is their ability to drastically reduce energy consumption. By recycling waste heat, industries can lower their reliance on external energy sources, leading to substantial cost savings.

Environmental Impact: Reduced energy consumption directly translates to lower greenhouse gas emissions. KAY MVRs contribute to a smaller carbon footprint, supporting corporate sustainability goals and compliance with environmental regulations.

Operational Efficiency: KAY MVR systems enhance the overall efficiency of industrial operations. By providing a consistent and reliable source of heat, they ensure optimal process performance and reduce downtime

Cost-Effective: While the initial investment in KAY MVR technology may be significant, the long-term savings in energy costs and improved operational efficiency offer a compelling return on investment.

APPLICATIONS OF KAY MECHANICAL VAPOUR RECOMPRESSORS

Chemical Industry: Used in the distillation and concentration processes, KAY MVRs help in recovering valuable solvents and reducing energy costs.

Food and Beverage: KAY MVRs are employed in the concentration of juices, milk, and other liquid foods, ensuring high product quality while maintaining energy efficiency.

Pharmaceuticals: In the pharmaceutical industry, KAY MVRs are critical in solvent recovery and crystallization processes, contributing to both cost savings and environmental sustainability

Pulp and Paper: KAY MVRs assist in black liquor evaporation and pulp drying processes, essential for efficient pulp and paper production.

TECHNOLOGICAL ADVANCEMENTS AND FUTURE PROSPECTS

The landscape of mechanical vapour recompression is continually evolving, driven by innovations in compressor technology and material science. New developments are enhancing the efficiency, durability, and longevity of MVR systems. Additionally, advancements in automation and control systems are facilitating the seamless integration of MVRs into existing industrial setups, allowing for real-time monitoring and optimization.

As industries increasingly prioritize energy efficiency and sustainability, the adoption of MVR technology is set to rise. The dual benefits of economic and environmental improvements make MVRs indispensable in the future of industrial energy management.